- Details

- Category: Owner's Handbook

- Hits: 2486

Care Of The Tyres

The following simple suggestions will help towards long tyre life and freedom from trouble.

Always keep the tyres inflated to the recommended pressures. Do not omit to adjust the pressures when a pillion passenger is carried. See also page 47.

Check the treads regularly for embedded stones, gravel etc. Ideally this should be done at the end of each riding day. Removal of embedded material is easier if the tyre is partly deflated.

Check regularly front and rear wheel alignment. Mal-aligned wheels cause rapid tread wear, and bad steering.

Keep the tyres free from oil, grease, or paraffin. These attack rubber, causing deterioration. Use a petrol soaked rag to clean off any that gets on accidentally. At all times avoid violent acceleration and braking. This causes excessive tyre wear.

Tyre Pressures. The minimum pressures for the standard tyres fitted are : —

| Front tyre (solo) | 16lbs. per sq. inch. | 1.13 kilos per sq. cm. |

| Rear tyre (solo) | 18lbs.per sq. inch. | 1.26 kilos per sq. cm. |

It is advisable, if at all possible, to have the front, rear, and sidecar wheel laden weights checked on a public weighbridge, so that the pressures may be adjusted to suit individual requirements. When normal laden weights are noted the following table may be used :

Load in pounds on wheel fitted with 3.25 x 19-in. cover

| 200-lbs. | Pressure 16 lbs. per sq. in. | 1.13 kilos per sq. cm. |

| 240-lbs | Pressure 18 lbs. per sq. in | 1.26 kilos per sq. cm. |

| 280-lbs | Pressure 20 lbs. per sq. in | 1.4 kilos per sq. cm. |

| 350-lbs | Pressure 24 lbs. per sq. in | 1.68 kilos per sq. cm. |

| 400-lbs. | Pressure 28 lbs. per sq. in | 1.96 kilos per sq. cm. |

| 440-lbs | Pressure 32 lbs. per sq. in | 2.25 kilos per sq. cm. |

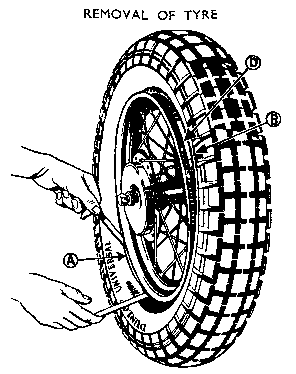

Removal of Tyre. Take off the valve cap, the valve retaining nut, and remove the valve core. When the tube is sufficiently deflated force both beads from the bead seating on the rim Covers tend to stick to the rim after some use. Insert a tyre lever between the bead and rim at the valve position and press down towards the wheel hub. At the same time it is essential, to permit easy removal of the first section of bead, to push the section of bead diametrically opposite fully down into the well of the rim. The bead is inextensible and the section at "A" (illustration, page 48) cannot be levered over the rim flange until the bead at "B" is pushed off the rim shoulder at "C" down into the well "D"

This can be accomplished by hand or foot pressure, whichever is easier.

Insert another lever a few inches from the first and again with pressure towards the hub prise off a further section of bead. Repeat this operation until the first bead is clear of the rim.

Push the valve through the hole in the rim into the cover and remove the tube carefully.

Stand the wheel upright and insert a lever between the remaining bead and the rim from the opposite side to the already free bead and with upward and outward pressure on the lever prise the cover off the rim.

Repairs to Tube. Before removing the rear wheel refer to page 50. Should the tube have become punctured it is preferable to have it vulcanized. Most Service Agents have the equipment. If a tube has to be patched be most particular to clean very thoroughly the surface to which the patch is to stick. Be sparing of solution on the tube and allow sufficient time for this to become really tacky before fixing the patch. Hurried patching on a badly cleaned tube will cause trouble later by patches lifting due to the heat generated in the cover when running.

Refitting Tyre. Slightly inflate the tube just enough to round it, but not to distend it, as a precaution against pinching when fitting. Fit the tube to the cover, noting that if the tyre has a balancing mark on the wall (sometimes a white spot is used) the mark must line up with the valve. Lay the tyre eccentrically over the wheel overhanging at the valve position and towards the operator, and with the valve opposite to the valve hole in the rim.

Squeeze the beads together at the valve position to prevent the tube slipping back inside the cover and push the cover towards the rim, threading the valve through the rim band and rim. Screw the valve retaining nut on for a few turns. Allow the lower bead to go into the well of the rim and the upper bead to lie above the rim flange. Working from the valve position press the lower bead over the rim by hand. When dealing with a new tyre which may be tight the work is eased by brushing soap solution half-way round the first bead, also the opposite half of the second bead. If necessary use a tyre lever for the last few inches. See that the bead lies well down in the well of the rim.

Press the upper bead into the well of the rim diametrically opposite the valve. Insert a tyre lever as closely as possible to the point where the bead crosses the rim flange and lever the bead over into the well. Work alternately from each side of the wheel gradually moving towards the valve, applying pressure with the left hand at each stage and retaining the bead under the rim by kneeling on sections already secured. Final pressure will take the complete second bead over the rim. By gradually working round from opposite sides the valve will be kept central in the hole.

Inflate tube to the correct pressure and at the same time check that the fitting lines on the walls of the cover above the rim flanges are concentric. Screw down the knurled ring and fit the valve cap.