- Details

- Category: Owner's Handbook

- Hits: 2420

Electrical Equipment

Battery Maintenance. Provided that the battery has been filled and charged for the first time exactly to the makers' instructions, it should need only a little routine attention to remain in good order.

Top up with distilled water regularly, usually every 1,000 miles, or more frequently in warm weather. It is easier to do this if the battery is removed.

Take off the lid and unscrew the three vent plugs from the battery top.

If a Varley battery is fitted there will be no free liquid in the cells, but the filling which is visible should be moist. Add a little distilled water to each cell. About a teaspoonful in each. Allow this to become absorbed before adding more. When the cells will not absorb any more water after standing about ten minutes shake out all excess, dry the top and replace the plugs. Refit the battery. The topping up should be done when it is needed after a journey, not before starting.

The level of the liquid in "wet" batteries such as Exide, Lucas, etc., must be high enough for the plates to be covered. A Lucas battery filler is obtainable which will automatically top up the cells the right amount. Failing this bring the level up to cover the plates, but not to cover the separators which stand higher and are often mistaken for them.

"Wet" batteries are best topped up before a journey. See that the terminals are clean, free from corrosion, and tight. Smear lightly with vaseline to prevent corrosion.

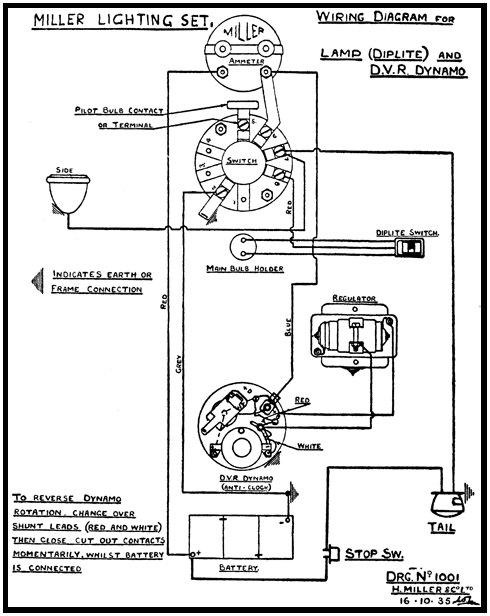

Before starting up check by switching on the lights that the battery is correctly connected. (Black -) negative to frame. The ammeter should show a discharge. If a "charge" is indicated switch off at once and correct the wiring. A wiring diagram is on page 69.

Battery Storage. If the motor-cycle is laid up for longer than a month the battery should be taken off and charged. Regular freshening charges will be required if storage con¬tinues. Do not in any circumstances empty the battery—this will ruin it.

At the commencement of storage, top up as already explained, charge on a charging installation until fully charged. Clean and dry externally, clean the terminals and coat them with vaseline. Give livening charges of 8 hours at 1 ampere monthly and keep topped up.

Lamps and Bulbs. The headlamp is fitted with one Bifocal bulb and one parking (Pilot) bulb. The types used are :

Headlamp Bulb-6-volt 30 x 24 watt ; Double filament ; Bifocal Pre-focussed type.

Pilot Bulb-6-volt 3 watt ; Single filament ; M.E.S. Cap.

To remove the lamp front to change a bulb or for other attention, free the clip below the lamp rim and pull the rim away from the lamp from the bottom first. Note that if it is proposed to do any work to the switch involving any connec¬tions, always detach the cables from the positive terminal of the battery.

The bulbs are detachable from the back of the reflector after removing the bayonet-fixed contact assembly to which the leads are attached.

To replace lamp glass and reflector unit release the four - or more fixing clips from under the lip of the head lamp rim. The unit will now come out of the rim.

Do not touch the highly polished inside optical surface of the reflector as this will leave finger marks which it will be most difficult to remove without damaging the surface permanently.

When replacing the reflector see that it is fitted correctly with the opening for the pilot bulb uppermost. Refit the lamp front at the top first - push it over the lower edge, engage the fixing clip.

The rear lamp and stop lamp are combined in one body and the bulb used is a 6-volt 18 x 6W offset pin Stoplight bulb, or 6-volt G.W. type S.C.C. when rear lamp only is fitted.

To reach the bulb take out two screws from the plastic "light" and remove.

Dynamo. If the charging is satisfactory it is advisable to leave well alone. The condition of the commutator and brushes should be checked occasionally and the segments of the former polished up if blackened. In any case carry out an inspection after 10,000 miles running. Before any inspection remove the positive lead from the battery.

Remove the commutator cover from the end of the dynamo remote from the drive by pulling out the single pin plug and taking out the cover centre screw.

The brushes must work freely in the brush holders, and if worn down so that they do not bear on the commutator evenly, or expose the embedded ends of the flexible lead on the run¬ning face they must be renewed.

Stiffness can be rectified by removing the tight brush and cleaning the sides with a petrol-moistened cloth, or by rubbing lightly on fine glass paper.

Clean all traces of oil or dirt from the commutator by pressing a cloth against it whilst rotating the engine with the kickstart. If very dirty use some petrol on the cloth. If blackened or ridged clean up by polishing with a strip of glass paper wrapped around the commutator segments. Note that if considerable polishing is done the mica inserts may need undercutting ; a job for a Miller Service Agent.

New brushes must be bedded down to the commutator before use and the work should be handed over to the nearest Service Agent.

Always, when refitting old brushes, see that they go back into their original positions.

The Automatic Voltage Regulator. This should need no attention at all in normal service, but if suspected of being at fault first check the dynamo belt adjustment.

The symptoms of defective regulation, i.e., under charging, may be caused by the belt slipping due to faulty adjustment - see page 33.

If the regulator is suspected of being at fault, consult a Miller Service Agent or have the regulator checked by substitution.