- Details

- Category: KSS, KTS Mk II OHC Instruction Book

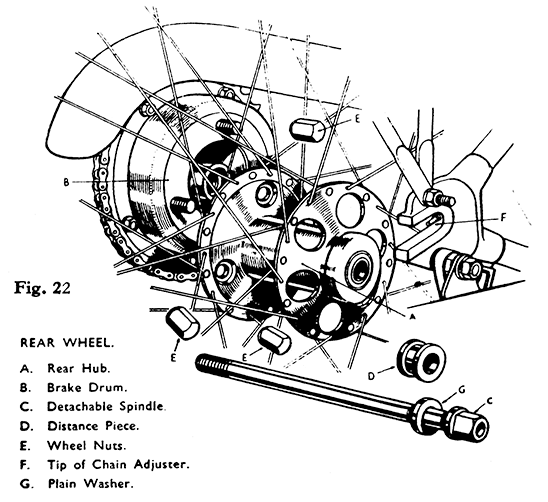

Removal and Replacement of Rear Wheel

Free the rear stand from the mudguard and raise the machine on to the stand. Always choose level ground, but if compelled to work on a slope, have the machine facing uphill, it is then unlikely to run forward off the stand when the wheel is out. Disconnect the rear lamp and detach the mudguard extension.

Loosen and take off the three nuts securing the wheel to the Brake-drum, unscrew and pull out the Spindle from the off-side. As it comes clear of the hub catch the distance piece, which is fitted between the hollow spindle of the hub and the Fork-end of the frame. Remove the wheel by lifting it off the studs and pulling it away to the rear.

Lift the wheel into place and fit the three wheel nuts to the studs on the Brake-drum. Place the distance piece in position inside the Fork-end of the Frame. See that the plain washer is in place under the head of the Spindle, screw in and tighten the Spindle fully.

Tighten the three wheel nuts fully and refit the mudguard extension.

After running about twenty miles after replacing the Rear wheel, check and if necessary tighten the spindle and wheel nuts, in case any bedding down has occurred.

Never lower the machine off the stand on to the wheel unless the Spindle is in position, and on no account remove this spindle unless the weight is taken off the wheel by placing the machine on the stand.

To change a rear Inner-tube it is not necessary to remove the wheel. The old tube can be removed and a new one fitted by removing the Spindle and distance piece.