- Details

- Category: KSS, KTS Mk II OHC Instruction Book

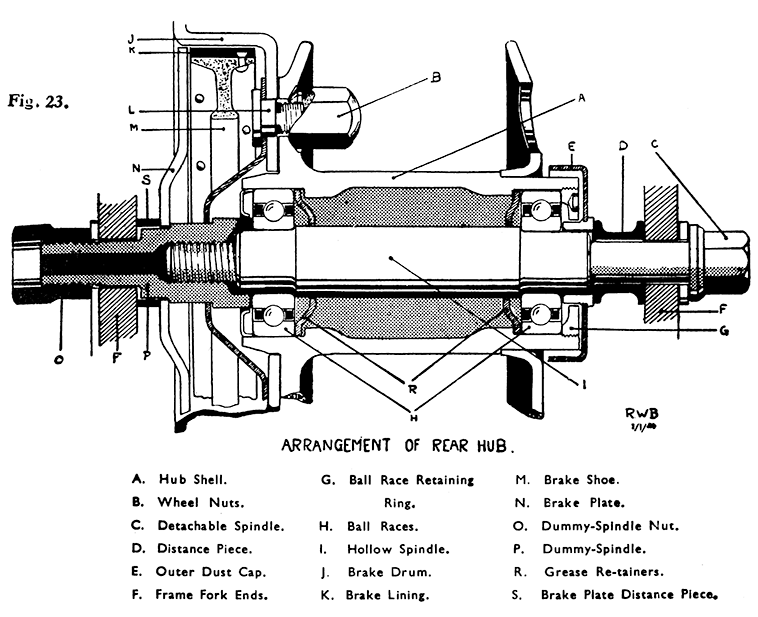

Dismantling the Rear Hub Bearings

Support the machine on the rear stand and take out the rear wheel as described on page 60. To remove the bearings a punch is necessary, and is made from round brass or aluminium bar of slightly under 7/8-in. diameter. The punch will have to be about 9-in. long, turned down at one end to just under 5/8-in. for a distance of about ½-in. This is used to protect the end of the Hollow spindle from becoming damaged when it is driven out.

Fit the reduced end of the punch into the hollow spindle at the right-hand side of the hub and drive the hollow spindle through the hub towards the other side by using a fairly heavy hammer (a 1-lb. hammer should be satisfactory). The spindle will leave the dust cap on the right-hand side and this can then be lifted off and the ballrace from the left-hand end of the hub will be forced out with the spindle and a small dust cap. This bearing, which will still be in place on the hollow spindle, can be cleaned and tested for wear. If any undue slackness is perceptible or if the bearing is felt to turn roughly, jerkily or stiffly, it should be replaced. If satisfactory it can be put aside until it is to be refitted. The bearings are not adjustable.

Now unscrew the ballrace retaining ring from the right-hand end of the hub using the peg spanner from the kit. The ring unscrews anti-clockwise. It will be possible then to check the condition of the bearing whilst it is in position. If satisfactory, pack it fully with grease and refit the retaining ring. Should it be necessary for the bearing to be renewed it must be driven out of the hub from the opposite side and it may be convenient to use the hollow spindle for this job. To do this, press the spindle out of the other ballrace and pass it through the hub from the left-hand end until it is pushed into the hole in the centre ring of the ballrace which is to be removed. Fit the punch into the other end of the spindle and drive the bearing out of its housing in the hub.

It should be noted that behind each bearing a steel washer is used to prevent grease working into the hollow centre part of the hub, where it can be of no use. Before refitting either of the bearings always see that these washers are in position (The concave surfaces are always towards the bearing). Also observe .carefully that the ends of the hollow spindle which are ground to the correct diameter to fit the bearings are not each ground for the same distance. The longer ground end must always be fitted into the bearing on the right-hand side and enters the hub first when re-assembling This apparently trivial detail is for all that of great importance because if the hollow spindle is put back incorrectly the wheel cannot be refitted to the machine properly. A replacement bearing can quite easily be pressed into the hub after the grease retainer has been fitted, and should then be packed full of grease. Now screw in the retaining ring and tighten fully.

Refit the other bearing to the shorter ground end of the hollow spindle, put the other grease retainer into place in the hub, concave face out¬wards, and slip the spindle through, fitting the other end into the centre of the right-hand bearing. Drive the spindle through until it is fully home and the left-hand bearing is down in its housing in the hub. Pack well with grease and press in the small dust cap. Finally, tap the right-hand dust cap on to the end of the hollow spindle. The wheel is then ready to put back into the frame.