- Details

- Category: F477 Owners Handbook

- Hits: 718

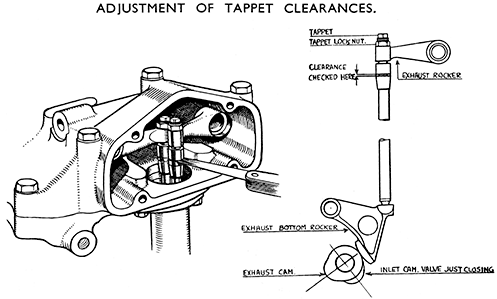

Adjustment Of Tappet Clearances

Readjustment of Tappet Clearances. The running clearances quoted are those which must be allowed when the engine is cold.

Checking and adjustment must also be carried out when the bearing surface of the bottom rocker is resting on the base of the cam.

Owing to the special profile of the cams which are ground with quietening ramps to take up and restore the running clearances gradually there is only a very limited section of each cam at which the clearance can be set correctly.

The crankshaft must be turned by means of the kickstart until the correct position for dealing with each valve is obtained.

The movement of the rockers should be observed through the opening in the rocker box as the crankshaft is turned forward.

Observe the inlet rocker—that nearest the cylinder—rise and continue turning the crankshaft slowly until the push-rod reaches its lowest point. This is the correct position for checking the exhaust clearance. Illustration above.

Before attending to the inlet clearance turn the crankshaft forward for two thirds of a revolution (240°) until the exhaust rocker is observed to be just about to rise. This is the position for dealing with the inlet tappet adjustment.

The clearances are checked by inserting the feeler gauge between the push rod end (fixed) and the loose ball cup, and are adjusted by slacking back the tappet lock-nut and turning the tappet in the rocker end with the spanner provided. A full turn of the tappet alters the clearance .038" approx.

Allow .005" clearance on both push rods.

Note.—Other clearances are employed when checking valve timing. See Service Manual.

After adjustment tighten the lock-nut and recheck in case the adjustment has been altered during the tightening. See illustration page 39.