- Details

- Category: F131-3R Instruction Book

- Hits: 818

Clutch And Gearbox

Machines now being delivered have NO ADJUSTER for Clutch cable at Gearbox end, as adjustment is set before delivery and further attention to cable is unnecessary. All adjustments to allow for bedding down and wear of Inserts must be made by turning Clutch Spring Carrier.

Adjustment of Clutch.

The clutch inserts tend to bed down with service particularly on a new machine, and in the first 100 or so miles running it is important to make certain that adjustment is made to compensate for the effects of bedding down. There should always be at least 3/16" free movement on the cable at the clutch lever end on the handlebar. From experience we find that the clutch cable never stretches appreciably. Any re-adjustment should be made by rotating the clutch spring carrier if additional free movement is required, see illustration. Place the machine on the rear stand, remove the nut securing the front portion of the rear chain cover to the stud on the primary chain cover and slide the cover out of position - it is telescoped into the rear portion of the rear chain cover.

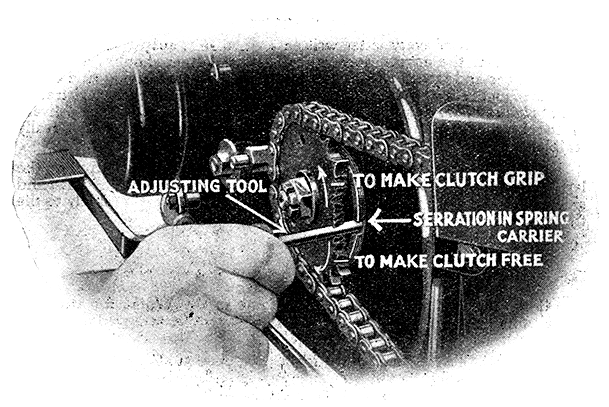

The sprocket will now be accessible and the clutch adjusting tool can be pushed through one of the holes in the sprocket and engaged with one of the serrations in the clutch spring carrier which is immediately behind the sprocket. The clutch spring carrier is pulled round anti-clockwise to increase free movement or clockwise to decrease it. This is done by pulling round the rear wheel.

If the adjustment has been lost altogether, or if a new cable has been fitted, slacken off the cable completely and screw in the clutch spring carrier clockwise until it is possible just to feel the clutch slipping when the kick starter is depressed. Now adjust the clutch cable until there is no slack in it. Do not force the adjustment so as to tend to withdraw the clutch, but just see that there is no slackness in the outer casing, Now with the clutch adjusting tool adjust the clutch spring carrier anti-clockwise as described previously, until the necessary free movement is obtained on the cable. If difficulty is encountered in moving the spring carrier due to the clutch slipping engage first speed and turn wheel until adjusting tool can be engaged with spring carrier and then pull wheel backwards. The differential action of the gears will then move the spring holder.

The illustrations show clearly the method of using the clutch adjusting tool.

Do not confuse the clutch spring carrier with the sleeve gear nut. The clutch spring carrier is provided with serrations, and the clutch adjusting tool or peg when passed through the hole in the small gearbox sprocket will engage with the serrations of the spring carrier. On later machines the cable adjuster is not fitted to the Gearbox. The cable does not need re-adjustment in normal use.

There is no necessity to remove the sprocket for purposes of adjustment and no attempt must be made to turn the sleeve gear nut unless it is desired to remove the complete clutch from the machine.

It is very important not to run the machine with the clutch slipping, and adjustment should be made immediately it is necessary. If the adjustment is correct oil will not cause clutch slip. The clutch is designed to run with oil in Chain Cover. If, for any reason, the clutch is left in a slipping condition, the inserts may become charred, and this will decrease their co-efficient of friction, consequently if slipping has been going on for any length of time and adjustment does not recify it, it will be necesary to dismantle the clutch and to clean the surface of the inserts or to fit new inserts.

VERY IMPORTANT. Failure to maintain the adjustment so that there is sufficient free movement in the clutch operating mechanism will be likely to cause serious damage to the clutch thrust race owing to this being subjected to a heavy and constant thrust load which it is not intended to carry. When the adjustment is correct the thrust race carries no thrust load when the clutch is engaged.

Dismantling the Clutch and Re-assembling.

First remove the dynamo belt cover, the belt, the back portion of the belt cover, the rear chain cover and the gearbox sprocket and rear chain. Take off the outer portion of the front chain cover and remove the sleeve gear nut part C.5. by turning this anti-clockwise with the pegged spanner provided in the tool kit. Take care when removing the chain cover not to damage the cork packing washer which is used between the two halves. (See note re Shock Absorber and Chain, page 17).

The clutch will now pull off the sleeve gear complete or can be taken off by first pulling off the clutch front plate with the spring carrier and springs then sliding off the clutch chain wheel and its race and finally pulling off the clutch back plate. Remove the three thrust pins from the back plate otherwise they will drop out and be lost. The cork inserts will wear until they are practically flat with the steel plate.

After the removal of the clutch back plate, the clutch thrust race, the thrust washer and thrust cup are accessible for examination. Put a little grease on the thrust race before re-assembling also a little grease between the balls in the chain wheel ball race. The ball race should be tight in the chain wheel and an easy fit on the centre bearing of the clutch back plate.

To re-assemble slide on the clutch back plate. Slip the three thrust pins into position, put back the chain wheel, the clutch front plate, and screw up the sleeve gear lock nut. It is best to engage top gear before refitting sleeve gear nut as this will prevent the sleeve gear being pushed into gearbox. Finally proceed with the adjustment as previously described. Should the clutch chain wheel require new inserts fitted it may be sent to these Works for this to be done - the charge is 4/- return postage extra.

Dismantling And Reassembling The Gearbox

Drain out all oil. The drain plug is at the back of the gearbox in the centre. It is unnecessary to remove the gearbox from the machine to dismantle it, and it is easier to leave it in position. Take out the three bolts holding the kick start housing B.K.4 to the gearbox end cover. Pull out the housing complete with the kick start crank and ratchet B.K.14. Unless it is required to change the kick start spring B.K.19 do not dismantle the ratchet from the housing. On machines which are not fitted with kick starters the layshaft cap B.K.94 may be left in place.

Unscrew and remove the gearshaft end bearing cap B.3. from the gearbox end cover. Take off the hexagon nut from the end of the shaft and remove the rear chain cover and rear chain. Tap the gearshaft into the box about an inch. Take out all the end cover bolts and if a Footchange is fitted disconnect the gear rod from the outside sriking lever and remove the complete footchange. Take off the nuts from the ends of the selector bars. The ends of the bars protude through the end cover. It will now be possible to remove the end cover. Hang up the packing washer out of harm's way till needed when refitting.

Now draw out the two selector bars. If the nuts are threaded back on to the bars they will serve as a seating for levering out of place. Alternatively if a piece of steel about 3/8" thick and long enough to span across the gearbox housing is drilled to fit over the bars the nuts can be packed with washers and when screwed down will draw the bars out. The low gear will pull off the end of the gearshaft and the middle gear B.78 with selector fork B.K.26 may be taken out after the gearshaft has been pulled out from the clutch end of the gearbox.

Lift the bottom selector fork until the peg is disengaged from the track in the cam plate which will allow the layshaft complete with fork to come out. The two end gears on the layshaft are a tight press fit and are difficult to remove without a press. There should however be no necessity to disturb them.

On machines fitted with close ratio gears when a 17T sleeve gear B 6 /3 is fitted, the layshaft driving gear B.86 /2 (27 Teeth) will only disengage from the sleeve gear in one position. It will therefore be necessary to turn the lay-shaft round until this one position is found. This is on account of the teeth of the Top-gear "pickup" masking the sleeve gear teeth. Similarly the layshaft can only be refitted in this one position. Do not remove the camplate or any part of the striking mechanism as this may be very difficult to replace correctly. Re-assembly is simply a reversal of the operations described above.

Kick Starter

To change the kick starter return spring B.K.19 first take off the kick start housing complete (see above). Take off the nut from the kick start cotter and drive out the cotter using a soft metal punch to avoid damaging the threads. Take out the spring anchor peg B.K.73 /2 from the top of the housing. The crank simply pulls off the end of the ratchet or the ratchet may be tapped through the housing. It will bring the spring with it.

Fit one loop of the new spring over the peg in the ratchet. See that the thrust pins K191 and the engaging spring B.K.19 /2 are in place and refit the ratchet and spring into the housing, setting the spring and ratchet in such a position that the other loop is below the hole in the housing through which the anchor pin fits. Screw in the anchor peg taking care that its projection is engaged with the spring loop. Hold the large end of the ratchet in a vice and turn until the spring is in tension and the crank cotter and crank can be refitted.

For those owners of Velocettes who do not possess a vice it is sometimes difficult to get the necessary tension on the return spring while fixing the kick start crank on its shaft. A simple method is to knock two nails from which the heads have been removed into the bench. These nails must be spaced the same distance apart as the oilways in the ratchet, which is slipped over them and held firm while the housing is twisted to give the necessary tension to the spring.

Refit the cotter with the threaded end towards the rear of the Machine. Finally refit the complete housing to the end cover making sure that the thrust washer B.K.82 is in place in the ratchet. Refill with engine oil, see page 7.