- Details

- Category: Rigid Frame MAC Service Manual

- Hits: 1990

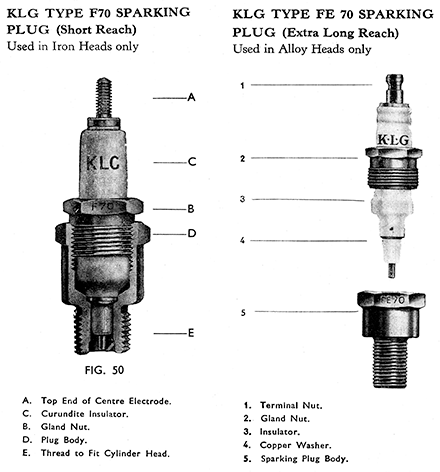

The Sparking Plug

Sparking plugs which are " detachable," i.e., those that can be taken apart for cleaning such as the, K.L.G. FE70, which is standard equipment on the MAC are easily dealt with when they become dirty.

It will be seen from the illustrations that the gland nut (2) can be unscrewed from the body (5) allowing the insulator and electrode assembly to be taken right out. If a K.L.G. Patent plug detacher is not available hold the gland nut in a vice or in a tubular spanner and screw the body off the gland nut. If a vice is used be most careful only to hold the nut firmly enough to stop it turning. Do not grip it tightly or it will be distorted out of round. Do not lose the gland washer (4).

Scrape all carbon deposits out of the plug body, and from the internal insulating surface. The insulation can be cleaned by wire brushing or rubbing with emery cloth.

To put it together again first see that the gland washer is in place, and smear it very lightly with a little thin lubricating oil. Put the insulator and electrode assembly into the body and start the gland nut into the thread. Again hold the gland nut and tighten the body on to it.

Adjusting the Firing Points.

After some use and always after cleaning, the firing points will need resetting to the correct gap. The adjustment is made by setting the side electrode (or electrodes) and never by bending the centre electrode. Any attempt to bend the centre electrode will almost certainly crack the insulator and cause plug failure sooner or later.

Carefully bend the side electrodes to give a gap of .018-in. to .023-in. Check gap with a feeler gauge.

Before fitting the plug to the cylinder head clean the thread and smear it lightly with graphite grease. After fitting give the external insulation a wipe over with a clean dry cloth.

SPARKING PLUG. Recommended Types.

Sparking plugs are produced in a wide variety of sizes, which includes different diameter threads and threaded portions of different length, i.e., different " reach." Each maker of plugs also lists plugs of widely different characteristics suitable for the many different types of internal combustion engines.

It does not follow therefore, that if a new plug is obtained that will screw into the sparking plug hole it is suitable for the engine. In fact if it is of incorrect reach or the wrong heat resistance grading for the engine it may cause a lot of harm.

The owner of the motor cycle should therefore not accept without question any plug offered for sale, but should insist upon getting the correct type of plug that we specify for the engine of his machine.

In order to give a choice we list below plugs of three makes which we know are suitable for the engines of the models covered by this Service Manual. The MOV and MSS (Rigid frame) models all have cast iron cylinder heads bored to take 14 m.m. Short reach plugs, and this also applies to MAC models up to and including Engine number MAC16459. These engines also have cast iron heads. For the MAC engines following, the 14 m.m. extra long reach type plug is used.

The plugs recommended by us are :-

|

Model MAC (Aluminium head) |

Champion |

NA 8. |

|

|

Lodge |

HLN. |

|

|

K.L.G. |

FE 70. |

|

Models MOV and MAC (Cast iron heads) |

Champion |

L 10S. |

|

|

K.L.G. |

F 70. |

|

|

Lodge |

H 14. |

|

Model MSS (Rigid frame) |

Champion |

L 11S. |

|

|

Lodge |

HH 14. |

|

|

K.L.G. |

F 80. |

Maintenance of Sparking Plugs.

The instructions above do not apply to the cleaning of plugs with mica insulation. Plugs of this type must in no circumstances be cleaned by sand blasting on the usual type of Service Station cleaning equipment nor must the mica be cleaned by scraping or rubbing with emery cloth or similar abrasive. Clean such plugs only with rag and petrol.

The plugs fitted nowadays have ceramic insulators of an exceedingly hard nature and these can be cleaned by the sand blast method if necessary and if the plug is of the " non-detachable " type.

As there is always a risk of some of the sand remaining up inside the body of the plug after sandblasting however, we consider that it is better to clean out accumulations of oily carbon by brushing with a small wire brush and then to wash out the gas space with petrol. In any case never refit immediately any plug which has been cleaned on a sand-blast apparatus without making sure that the interior is cleared of all sand. A really thorough washing in petrol and scouring out with a jet of compressed air is really essential.