- Details

- Category: Rigid Frame MAC Service Manual

- Hits: 2540

Decarbonising & Grinding In Valves

Although basically similar to previous MAC engines, the modifications made when the aluminium alloy cylinder head and aluminium alloy jacketed cylinder were introduced make slightly different procedure necessary when dismantling the cylinder head.

The cylinder head now contains the overhead rockers, valve springs, and rocker bearings and the earlier pattern separate rocker box is deleted.

It is generally desirable to decarbonise the engine and to grind in the valves lightly on a new machine after it has covered the first 2,000 miles. It is not, however, necessary to repeat the process at anything like such frequent intervals and often a very considerable mileage can be covered before it is necessary to decarbonise again.

The usual indications that this work is required are a falling off of power and tendency for the engine to pink excessively.

To dismantle the engine for decarbonising it is necessary first to remove the fuel tank. To do so loosen the front saddle bolt and slip the frame of the saddle away from the bolt. On models MOV and MAC the saddle frame is slotted to allow it to be lifted out of position, and this will allow the front of the saddle to be lifted to make the rear tank bolt accessible.

Turn off the supply of fuel at both taps, undo the union nuts holding the fuel pipe to the taps. Do not allow the fuel pipe to twist. If a tap is not tight, prevent it from turning with a spanner on the hexagon section. Take out the two fixing bolts at the front of the tank with their steel washers. On Models MOV and MAC take off the nuts holding the small strap across the bottom of the tank at the front and remove the washers and strap. Loosen the nut from the rear bolt, push out the bolt to free tank. The tank is then free to come away.

Unscrew the ring holding the mixing chamber top to the mixing chamber of the carburetter, and pull out the throttle and air valves by the cables and tie them up out of the way to the top tube of the frame.

Take off the two nuts and remove the plain washers from the studs attaching the carburetter to the cylinder head and take off the carburetter and fuel pipe.

Removing Rocker Box. (Engines with Iron heads only.)

This is done by unscrewing and removing the bolts securing the tappet covers to the side of the rocker box and top cover. Take off both covers, being careful not to drop and lose the small oil control washers which are fitted in the centres of the rockers and which are held in place there by the rocker thrust springs fixed to the covers.

It will usually be found that there is an accumulation of oil in the spring covers and this oil may overflow on removal of the covers. This is quite normal and in order.

Take off the rocker box oil feed pipe.

Next take off the nuts and washers from the studs securing the top flange of the pushrod tube to the rocker box.

Slide the top part of the pushrod cover down off the studs into the lower part.

It will be noticed that between the two paper packing washers that are used on the top flange joint there is a steel pushrod guide plate. When the rocker box is taken off be sure that this plate is not lost.

Finally, take out the three long bolts that hold the rocker box to the cylinder head. This will free the rocker box and it can then be lifted off.

Do not take apart the top and bottom halves of the rocker box as it is very unlikely that this will ever have to be done in the course of normal maintenance. The rocker bearings give almost indefinite service.

Removing the Cylinder Head. (Alum-Alloy type.)

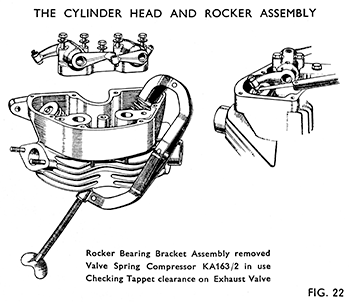

After removing the fuel tank and the usual items, disconnect and remove the oil feed pipe from the timing case to the rocker cover. Take out the eight cover bolts and remove the cover. Occasionally the rocker cover may foul the inlet rocker and be prevented from coming off. If this occurs rotate the crankshaft until the inlet valve is full open. This will give clearance for the cover to slide off towards the front end first. Remove the sparking plug. Rotate the crankshaft with the kick starter until both valves are closed and the piston at top dead centre or thereabouts.

Take out three bolts securing the rocker bearing block to the cylinder head - the two end ones and the centre one - but leave the other two in place.

Remove the bearing block and the rockers, and lift out the two push rods, which should be marked " inlet " and " exhaust " respectively. They must be put back into their own places on refitting. The inlet is the nearer to the centre of the machine. Indelible pencil, if wetted, is a suitable marking medium. Take off the gasket from the rocker bearing block platform.

Take off the nuts and washers from the studs which hold the upper push rod flange to the head, and telescope the upper section of tube into the lower half, at the same time taking off the push rod guide plate and the two joint washers from the flange face. This guide plate is an important and vital part of the engine, and must be preserved for refitting.

Unscrew and take off the four cylinder head nuts and washers - two accessible outside the rocker box on the left-hand side of the head - and the other two down inside the holes or openings in the bearing block platform.

Unscrew and take out the four long cylinder studs.

Lift off the cylinder head, retaining the cylinder head gasket for use when reassembling. Do not remove the cylinder.

Removing Cylinder Head. (Iron type only.)

Unscrew and remove the four cylinder head nuts—this will allow the cylinder head to be lifted off the barrel. No cylinder head gasket is fitted; a gasket was only used on engines prior to M3472, MAC 5079 and MSS 3611, and on engines with alloy heads.. It is unnecessary to remove the cylinder barrel, and we do not recommend it unless it has to be taken off for attention to the piston or piston rings, which is unlikely to be needed except after a considerable mileage has been run. The piston and piston rings should be disturbed as little as possible. Frequent removal and re-assembly sometimes causes heavy oil consumption.

Removing Valves and Springs (Alloy Head Model).

This is done in exactly the same manner as on the other models, but the Valve Spring Compressor Tool No. KA163 /2 is required to clear the sides of the rocker chamber. The smaller size used on the previous types is unsuitable.

The valve top washers, cotters and springs are identical to the corres¬ponding parts on earlier models, but there are loose bottom washers which fit over the valve guides and these come away when the springs are taken off.

Removing Valves and Springs. (Iron Head Models.)

The valves are removed by compressing the valve springs whilst holding the valve head on to the seating so as to allow the split cotter to be lifted out of the hollow in the valve-spring-washer. A (KA163) compressor will suit. After removing keep the two halves of each cotter together. The odd halves are not interchangeable. The valve springs, valve-spring-covers and washers, etc., are interchangeable, but it is best to refit them in the same positions from which they were removed. The valves are also interchangeable on MOV and MAC Models. The best plan is to get two small boxes, marking them respectively " inlet " and " exhaust." and place the parts into the appropriate boxes as they are taken off. The inner valve springs are a tight fit within the outers. Do not separate them.

Having removed the valve-cotters the springs can be released, which will permit them to be taken out and the valve spring covers to be removed from the guides.

It should be noted that inside each cover there is a plain steel washer which provides a seating for the bottom of the valve springs, and underneath each cover and between the cover and the guide there are two packing washers which should be renewed when re-assembling the engine.

The valves will pull out of the guides and should be thoroughly cleaned.

Refacing and Grinding in Valves, etc.

Reface the seatings on a valve grinding machine equipped with a collett if such a machine is available. The seat angle is 45°.

An alternative method is to hold the stem carefully and as close to the head as possible in the chuck of a lathe or drilling machine, being careful not to mark the stem or otherwise damage it.

The valve head can then be cleaned and polished up with ordinary emery cloth, a fine grade being used for finishing purposes. It is desirable to true up the valve seats, before grinding in the valves because although a valve is a comparatively cheap replacement it is necessary to avoid wearing the seats in the cylinder head by prolonged grinding as the head or seats are expensive to replace.

To remove the carbon from the cylinder head it is best to use a scraper made from some soft metal such as brass. This will avoid scratching the surface of the head or damaging the valve seats. Scrape the carbon from the combustion space and from the exhaust port and finish off by cleaning up the ports with emery cloth.

Avoid scratching the valve seats when doing so.

It is unlikely that the seatings in the cylinder head will require truing up unless the machine has covered a considerable distance.

If recutting is needed see Page 55.

If the seats appear to be in reasonably good order, the valves should be lightly ground in. To grind in the valves, use a very fine emery powder mixed with oil or paraffin, or one of the numerous brands of valve grinding compounds. These compounds are sometimes put up in a double-ended tin, the coarse compound in one end and fine compound in the other. It is very seldom necessary to use the coarse variety on the valves. Use as little compound as possible smeared over the seating on the valve. Avoid getting any compound on to the stem or into the valve guide.

Slip the valve into position and hold the end of the stem near the cotter groove with a suitable holder (KA164 /2) which should be tightened on to the valve carefully to avoid damaging the stem or the edges of the cotter groove.

Rotate the valve backwards and forwards, maintaining the valve head in contact with the seating by pulling lightly on the stem. Lift the valve frequently from the seating to prevent the formation of concentric rings and bring it down into another position, recommencing the back and forward movement for a further period.

A light coil spring can be used under the valve head to lift the valve off the seat when the pressure on the valve is removed.

After a few minutes light grinding the holder should be removed and the valve taken out. The compound should be wiped off the valve and off the seating in the head. The seatings should be a light grey in appearance, free from marks or black pits. As soon as a light grey seating is obtained all round the seat of the valve and all round the seat in the head, the grinding-in operation is complete, and the other valve should then be tackled.

Refitting Valves and Springs. (Iron Head Models.)

Before re-assembling, wash the valves and cylinder head very carefully in clean paraffin and wipe dry. Be particularly careful to see that there are no traces of valve grinding compound on the valves, and particularly in the guides.

Obtain four new packings and fit two in place over one of the valve guides. Place the valve spring cover in position and then fit the valve spring bottom washer in place over the valve guide inside the cover.

Put the valve springs into place, followed by the top washer, and after smearing the valve stem with lubricating oil, push the valve up into place, making sure that the stem comes through the top washer. The valve springs now have to be compressed again so that the two halves of the cotter may be refixed. If the insides of the cotters are lightly smeared with grease this will help to hold them to the stem whilst the valve springs are released again.

When compressing the valve springs either to remove or replace the valves be very careful to avoid damaging the spring-covers. If these are " burred " or set out of round it will not be possible to make the joints oil tight.

When fixing the cotters, make sure that the small lip on the cotter registers correctly with the groove in the stem of the valve.

If desired, a small quantity of jointing compound may be used on the asbestos washers, but this is not actually necessary. Jointing compound, however, is necessary for remaking the other joints on the engine (except the cylinder head joint, which will be dealt with later) and for this purpose we recommend Gasket Goo, which, after long experience we have found to be very satisfactory.

As an alternative jointing compound if Gasket Goo is not available, Seccotine is satisfactory.

Refitting Valves and Springs. (Alloy Head.)

The procedure is similar to that detailed above, but no gaskets need attention at this stage.

Cleaning Piston Top.

To clean the carbon from the top of the piston, bring the piston to the top of the stroke. A soft metal scraper as previously recommended for the cylinder head is necessary to avoid scratching the piston crown.

Scrape the carbon away and clean the top of the piston as much as possible with rag. Do not use emery cloth to clean the piston crown. Should this be used small abrasive particles of emery would be sure to get down between the piston and the cylinder and would rapidly prove disastrous to the engine. To remove all traces of carbon which have worked down between the top of the piston and the barrel push the piston slightly down into the bore and wipe away the carbon. Should the cylinder barrel have been taken off, the piston can best be cleaned after removal from the engine, as there is then no risk of pieces of carbon dropping into the crankcase.

The Cylinder Head Joint. (Iron Head Models.)

See note on page 47 regarding gaskets.

The joint is made between the cylinder head and the barrel, these two parts being lapped together during original assembly, so that the surfaces are quite flat. Do not attempt to prevent a leakage by tightening the cylinder head nuts. In the unlikely event of this joint leaking, remove the head. It can be re-ground to the barrel without the slightest difficulty. It is better to take the cylinder off the engine, but the work can be carried out with the cylinder in position if the four long cylinder studs have previously been taken out.

If the work is done in this way, however, great care must be taken to make sure that no trace of the grinding compound which is used for lapping the head to the barrel is allowed to get down between the cylinder bore and piston, as owing to its abrasive nature it would naturally cause damage very quickly. To carry out the actual grinding-in operation, a small quantity of fine grinding compound mixed with oil should be smeared on the two lower faces on the top of the cylinder, and the head slipped into position on to the barrel and then rotated backwards and forwards in order to grind the surfaces together.

It is desirable to raise the head slightly from time to time, and bring it down into another position in much the same manner as described previously to be adopted when grinding in the valves. Having completed the grinding, which should leave a smooth, grey surface on the cylinder and cylinder head, it is necessary to clean the faces carefully of all traces of compound. Fit the sparking plug to the head.

Where " Tighten " is stated, remember that overtightening may cause serious damage through stripped threads or broken bolts and studs.

Refitting the Cylinder Head, etc., after decarbonising.(Alum. Alloy type.)

Refit the cylinder head gasket, and the head. Fit the four long cylinder studs, the four cylinder head nuts and washers and tighten down evenly. Be careful not to overtighten, as the tension on the studs increases as the engine heats up, and if the nuts are strained down there is a grave risk of damage occurring.

Place the push rod guide plate with a joint washer on each side of it over the push rod flange studs in the head, and push the upper flange up and over the studs. Fit and tighten the two nuts.

Check that the piston is at top dead centre of compression stroke and reset to this position if necessary, and thread the two push rods down through the pushrod guide plate and engage their ball ends in the cups formed in the cam followers.

The object of setting the crankshaft so that the piston is at top of compression stroke is to allow the rockers and bearing block to be fitted without the valve springs having to be compressed. If the crankshaft has been moved from the position in which it was set before removing the bearing block and has to be reset, the fingers may be rested on the tops of the push rods and their up and down movements observed as the crankshaft is rotated. By turning until the inlet (inner) push rod lifts and then drops and then turning the crankshaft very slowly whilst observing the piston through the sparking plug hole the correct setting is easily found.

Place the bearing block gasket in position, fit the bearing block, entering the tips of the rockers in the cups on the push rods, and refit and tighten the three bearing block bolts.

Spin the push rods with the fingers to check that they are seated properly in the cups at the bottom.

Refitting the Cylinder Head (Iron type only.)

When re-assembling the cylinder head do not use any jointing compound on the face joint.

The sparking plug should be fitted to the cylinder head and screwed down before the head is fitted to the barrel, otherwise any small pieces of dirt which may have collected in the sparking plug threads will be forced out of the plug hole into the combustion chamber and cause damage to the cylinder bore or the piston.

Screw down the four cylinder head nuts on the long studs until they are each in contact with the head, and then begin to tighten them down further, evenly, and in turn, that is to say, do not tighten one nut fully without touching the others. DO NOT IN ANY CIRCUMSTANCES TIGHTEN THESE NUTS EXCESSIVELY. A good gastight joint is obtainable without forcing the nuts. The tension on the cylinder studs tends to increase as the engine heats up, and excessive tightening of the nuts in the first place may quite possibly involve serious damage to the engine.

Refitting the Rocker Cover. (Alloy Head Model.)

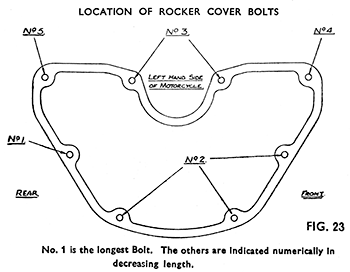

After resetting tappet clearances, fit a new gasket, replace the cover and tighten the eight bolts carefully and evenly. See Fig. 23. Refit the oil pipe.

Refitting the Rocker Box. (Iron Head Models.)

Assuming that the rocker box has not been taken apart, it is necessary only to scrape off carefully any traces of the old jointing compound from the surfaces to which the tappet covers are attached and around the inside of the recesses which fit against the steel valve spring covers.

The latter surfaces should then be smeared lightly with good jointing compound (Gasket Goo, Seccotine or Gold Size). The tops of the Platforms on the cylinder head and the underside of the rocker box bosses which fit on to them should be cleaned, and the rocker box fitted into place. The centre bolt must be in place in its hole before the rocker box is placed in position, as it cannot be put in afterwards on account of the top frame tube.

Make sure before fitting the rocker box, however, that the pushrods are in position, together with the guide plate and paper packing washers (one on each side of the guide plate), and see that the pushrods are engaged properly with the top and bottom rockers. Tighten the three bolts evenly and firmly, but not excessively. The joint surfaces at the top of the pushrod cover can then be smeared with compound and re-assembled.

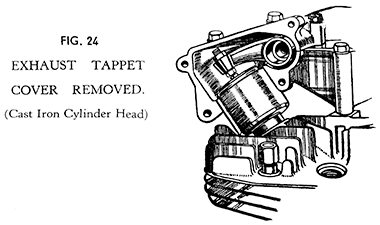

Next in order the tappet clearances should be dealt with. The method of re-setting and correct clearances are given later. Having adjusted the tappets correctly, which should be done with the engine cold, clean the faces of the tappet covers, both the flat surfaces and the curved joint surfaces being dealt with at the same time.

See that the oil control washers are in place in the centre bosses of the rockers, smear the joint surfaces of the tappet covers with compound as described above, and fit the covers into position carefully, slipping the bolts through the holes and tightening them up evenly and a little at a time.

Care is necessary when dealing with these bolts not to overtighten them they can be snapped off if excessive force is used.

Finally, refit the oil pipe to the timing cover and the rocker box, being careful not to overtighten the hollow bolt which secures the pipe to the rocker box cover.

Two fibre washers are used on this pipe, and one of these should be on either side of the banjo union.

Resetting the Tappet Clearances.

The cams are ground with quietening ramps and the positions at which the cams are set when checking or adjusting the clearances is therefore rather critical. Check and set when engine is cold.

When setting the inlet clearance set the crankshaft so that the exhaust valve is on the point of opening and turn it until the inlet valve is on the point of closing before setting the exhaust clearance.

(Different clearances are employed when checking the valve timing. See page 66.)

One turn of the tappet gives .038-in. variation in clearance (approx.)

To make the adjustment, slacken off the locknut, which is screwed on to the tappet and is above the end of the rocker.

Then turn the hexagon tappet head, which is below the rocker, to the right, to increase the clearance, or to the left to reduce it.

Check the clearance with a clearance gauge and tighten the locknut whilst the tappet head is held with a second spanner. After tightening the locknuts check the clearances again to be sure that they have not been altered whilst tightening the locknut.

To find top dead centre of compression stroke, refer to paragraph " Checking the Valve Timing " (Page 66).