Most of the manufacturers of sparking plugs produce a range of plugs that includes a variety of types to suit different makes and types of engines. The plugs differ in thread diameter, length of thread (reach), and also in their characteristics. It therefore does not follow that a sparking plug that will fit the threads in the cylinder heads will be suitable for the engine. The type of plug must of course be of the right reach and fit the threads, but also, and quite as important is that it must be of the correct internal heat resistance grading for the normal running conditions in which the engine is expected to work.

The Valiant is fitted with two K.L.G. 10 m.m. diameter, reach plugs type Ten L100. Replacements, if not of the same make must be equivalent in heat resistance values. The use of sparking plugs of different reach, or of unsuitable type will cause unsatisfactory running at the best, or serious trouble at the worst.

The. K.L.G. plugs fitted as standard equipment can be taken apart for cleaning. Other types may not be capable of being dismantled and will require different treatment.

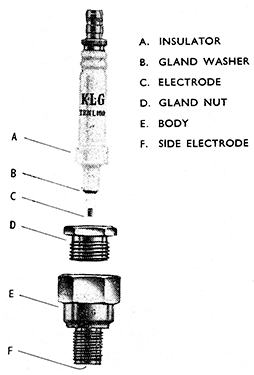

To take apart a plug the gland nut (D) has to be unscrewed from the body (E). Do not hold the body in a vice as this will contract it and probably make it impossible to unscrew the gland nut. If care is taken the gland nut can be held, with the plug inverted, in the vice, but the jaws must be covered to protect the hexagon, and only very light pressure must be used. Probably the best method is to hold the gland nut in one spanner a tube spanner held in a vice) and unscrew the body with another.

Clean all parts in petrol and scrape the body out with a small penknife or wire brush. Clean the metal electrode with glasspaper or emery cloth. Do not lose the copper gland washer (B).

FIG. 51 K.L.G Ten L100 Spark Plug

When clean lightly coat the gland washer with thin oil and refit the insulator assembly (A) to the body. Fit and tighten the gland nut.

Sparking plugs can be cleaned without being taken apart by brushing the electrodes and as far inside the gas space as possible with a small wire brush. A suitable brush can be made by filling the end of a piece of copper petrol pipe (about 1/8-in. bore) with as many strands of old control cable wire as possible and flattening the end of the tube to hold the wire firmly in place. The protruding strands are then cut off evenly about ½-in. from the tube.

Failing this cleaning can be done. at a Sparking Plug Cleaning Station. After cleaning on such equipment however the greatest care must be taken to get out of the gas space all traces of the sand cleaning medium. Particles can lodge up in the crevice between the insulator and the body, only to become dislodged later and get into the cylinders.

A really thorough blowing out by means of high pressure air jet, and careful cleaning in petrol are essential.

Reset the gap to .018-in. to .023-in., but do this by bending the side electrode (F). Never bend the centre electrode, as this will invariably crack and break the insulating material surrounding it.