This consists of a stator plate (an aluminium casting) carrying on the outside (the front) two high tension coils, a contact breaker, a condenser, and a ballast resistance. These are all visible when the cover has been removed (Fig. 3). On the other side three low tension generating coils are fixed by six 2BA screws to the casting. The flywheel completes the assembly. It is a brass wheel with six inserted permanent magnets, separ¬ated by six laminated soft iron poles. It is mounted on a steel centre internally tapered to fit the flywheel shaft.

The fitting of the flywheel to the shaft is important, and it is set during initial assembly so that the moving pole pieces relative to the fixed pole pieces of the generating coils at the instant the contact breaker points separate will give the maximum intensity of spark at the plugs. It follows therefore that it is best to avoid disturbing the flywheel if at all possible. Resetting can be carried out without special equipment in case of necessity, but accurate fixing calls for the Service Tools LET 952, and LET1138. See pages 41 and 42.

Take off the two fixing nuts and pull the cover off forward. There is a small lip at the bottom by which it can be levered if it sticks. Do not remove the cable support pressing from the Stator plate.

There will be some sparking at the contact points in normal working. This is desirable, and attention is only necessary if it becomes excessive when running with the switch in the Ign. & Ch.' position. In such a case remove the condenser and check by substitution.

To remove, take out the round head screw fixing it to the stator plate, and a similar screw attaching the condenser lead to the contact breaker.

If no substitute is available the condenser can be tested by applying a direct current lighting mains voltage to the terminal and the body. A lamp bulb of similar voltage must be connected in the mains circuit in series to prevent a short circuit should the condenser be defective or break down during the test.

If the condenser is in order, on cutting off the mains current and pausing a few seconds, an appreciable snappy spark will be obtained on short circuiting the condenser lead to the body.

No spark will be obtained from a leaky, or partly short circuited condenser, and one in this condition should be discarded and replaced.

The main body of the unit is taper fitted to the front end of the flywheel shaft, and the cam is free to move upon it radially within the limits imposed by the mechanism. Two weights each controlled by a light coil spring are pivoted to the body and any movement outwards advances the cam in relation to the body and of course the shaft to which it is fitted. When at rest the weights are held closed ' by the springs and the ignition setting is retarded. When the engine starts and the speed increases centrifugal force acting upon the weights overcomes the restraint of the springs and they begin to move outwards advancing the ignition.

The unit does not need maintenance attention and should not be disturbed without very good reason. It must be removed to replace contact breaker points, and can be drawn off the taper with the extractor bolt LET948. When refitting be very careful not to overtighten the fixing pin as this may expand the centre and prevent the cam moving on it thus 'fixing' the ignition on full retard. For this reason do not use the head of the pin as a purchase to turn the crankshaft for tappet setting, or retiming, etc. See also page 29.

The Ignition Cam Lubricating Pad.

This is fitted on a pin alongside the cam on the right and the grease impregnated felt is in contact with the working surface.

Apply a little soft grease to it at intervals of about 2,000 miles working the lubricant well into the felt. Do not overgrease as the excess will get on to the contact points causing them to deteriorate quickly. The surface of the cam only needs to be kept very slightly greasy.

Fitted to the headlamp body. With the switch ' off ' and engine stationary the needle should be central on the dial at zero. On switching on any lights the amount of current they are consuming will be registered on the discharge (left) hand side of the scale. Occasionally the engine will stop in such a position that the contact points are touching. This will increase the discharge, and it will show in such circumstances if the switch is on Ch. & Ig.' with no lamps on.

Should the ammeter show a charge ' on the right hand side of the scale at any time that the lights are switched on and the engine is not running, it is definite indication that the battery has been incorrectly connected.

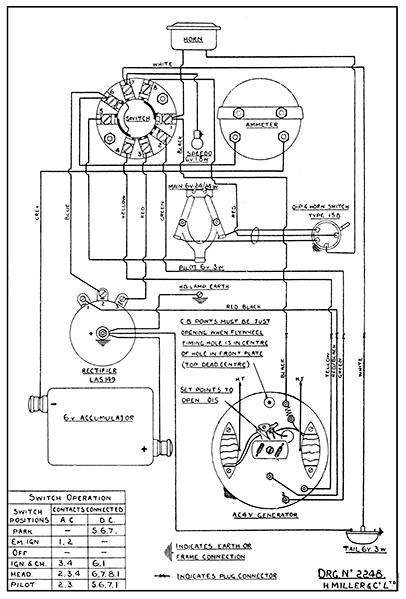

The battery must be connected positive (+) to frame (earth), see wiring diagram Fig. 47.

FIG. 47 WIRING DIAGRAM FOR MILLER AC4 GENERATOR RECTIFIER SET

The open circuit voltage (A.C.) measured across the Red /Black terminal and Green (No. 2) should be 15 volts at 2,000 r.p.m. (i.e., about 30 m.p.h. in top gear) with a maximum of 40 volts.

The resistance ot the generator coils measured across these terminals should be .55 ohm. and .275 ohm. respectively. The high tension coil primary windings are connected in series and the resistance measured across the ignition terminal Black and the contact breaker should be 1.1 ohms. (.55 ohm. per coil). When making this check connect the checking leads to the ' coil end of the ballast resistance and the contact breaker, as inclusion of the ballast resistance in the circuit will give a false reading.

The secondary winding resistance is approximately 3,900 ohms. per coil measured across the high tension lead and the contact breaker (primary). When the contact points are separated (open) the ignition coils are isolated from the frame (earth).

Electrical Fault-finding Chart

| Fault | Probable Cause |

| (1) Lamp bulbs burning out. | Poor connections in battery circuit. Faulty battery (Sulphated or dry). |

| (2) No lights. | Short circuits or breaks in wiring to lamps. Switch contacts 5.6.7. or 8, not making good contact with switch rotor. |

| (3) Difficult starting in emergency ignition position. | Incorrect ignition timing. Flywheel set incorrectly in relation to shaft. Contact breaker gap too small. (Correct gap is .015-in.) |

| (4) Misfiring in ' Ch. & Ign.' position. | Dirty, greasy, or pitted contact points. Point gap too large. Weak contact breaker springs. Sticking or sluggish working of rocker arm pivot. Faulty, dirty, or unsuitable sparking plugs. Short circuits in high tension leads. Faulty leads. Bad connections between leads and suppressors. Short circuits or poor connections in battery or ignition circuits. |

| (5) Low charge rate | Short circuits, or poor connections in wiring (check all ' jack' connectors). Switch contacts, 2, 3 or 4 not making good contact with switch rotor. Rectifier imperfectly 'earthed'. Faulty rectifier (check by substitution). Faulty battery (Sulphated). Faulty generator coil. Flywheel demagnetized (this can be caused by wrong connections allowing battery current to flow through generator windings). |

The switch contacts that are connected in the six positions of the lever are shown in the panel on the wiring diagram.

Full wave rectification is obtained in the three normal running position of the switch as follows :

| Ign. & Ch | 2 amps at 2,000 r.p.m. | Maximum output 3 amps. |

| Head and tail | 4 amps at 2,000 r.p.m. | Maximum output 7 amps. |

| Pilot and tail | 3 amps at 2,000 r.p.m | Maximum output 5 amps. |

Notes on the Electrical System.

Before doing any work involving removal of engine cowling or disturbing electrical connections at the switch, bulbs, or generator always disconnect the negative (-) lead from the battery.

Do not make any alterations to the wiring without checking carefully with the diagram.

In some conditions of use the mileage covered without lights may exceed very greatly the periods when they are in use. In such cases where the demands upon the battery are very small a 30/30 watt headlamp bulb can be substituted for the standard one. Alternatively the machine can be run with the ' Snap ' connector of the Yellow lead parted temporarily. If this is done leave the rubber sleeve of the connector on the yellow part (the generator end) of the cable to prevent it short circuiting against any metal part of the machine.