Carefully check the mating faces of the crown wheel and shaft making sure that they are perfectly clean and entirely free from even the smallest trace of foreign matter that would prevent them coming into full contact over the whole area when the crown wheel is fitted. The slightest irregularity will prevent it running true.

Fit the crown wheel to the shaft and put in the six bolts. Note that these are special ones and if new ones are required do not use anything except the genuine replacement parts, and if a new crown wheel is being fitted always fit six new bolts and nuts.

The bolt heads fit against the back face of the crown wheel and the nuts against the flange face on the shaft.

Hold the shaft in the vice and tighten all nuts evenly and securely. Refitting the Crown Wheel Shaft to the cover.

Press the ballrace, or a new one on to the shaft up to the shoulder. Apply the pressure to the inner ring only.

Have in readiness for fitting, the oil seal (fitted to its housing), the fixed spindle inner washer, and the packing shims. If the originals have had to be renewed have new ones ready of the same total thickness. The correct thickness is essential to mesh the crown wheel properly with the pinion. A new crown wheel may require a different thickness from that used with the old one, but for the time being use the same as before for the initial trial setting. Corrections can be made later if they are needed.

Heat the cover carefully around the ballrace housing being careful not to overheat. When hot enough place in position in the housing the oil seal and housing, the inner washer, and the packing shims. Enter the ballrace at once setting it square with the housing and tap the shaft to get it fully home.

If the crown wheel is a new one check the position of the ballrace face with the side face of the housing by sighting across the housing under the back face of the crown wheel. When full home the ballrace is usually about .005-in. below with the shaft assembled in the cover.

Refitting the Crown Wheel Shaft and Cover to the Bevel Casing.

With the bevel casing resting on the bench, open side upwards, fit the two locating dowels over the studs into the counterbored holes. Fit the gasket, sticking it to the face with a little grease. Smear the roller track on the crown wheel shaft with some clean grease and stick the rollers (twenty-three of them) in place.

Take up the cover and shaft, enter the latter with the rollers into the steel outer race in the housing. Be very careful not to dislodge any rollers in the process.

Locate the cover over the studs and by hand pressure only push it down very firmly towards the face. Fit the eight lock-washers and nuts. If the original crown wheel and pinion are being fitted the nuts can be evenly and fully tightened down at once, but if the crown wheel and pinion are new and being fitted for the first time proceed as described on page 61.

Refitting the bevel Pinion Bearings.

Cover the roller track on the pinion with a little clean grease and stick the rollers (seventeen of them) in place around it. Carefully fit the pinion outer race, plain end first, over the rollers being careful not to dislodge them. The flanged end of the outer race must face the splines. The pinion collar is pressed on to the pinion and is unlikely to have shifted from the shoulder of the roller track.

Fit the pinion ballrace, pressing it home up to the pinion collar. Apply pressure only to the inner ring. Fit the tabwasher and the lockring the latter with the machined face contacting the tabwasher. Hold the splines of the pinion, as when dismantling, in the vice tool (Fig. 42) and tighten the lock ring securely. When tight bend back a tongue of the tabwasher into a serration on the ring.

Oil the plain part of the pinion above the lock ring and fit the oil seal and housing (previously fitted together). Do not refit the bevel pinion to the bevel housing before the propeller shaft coupling is pressed back on to the splines.

Refitting the Propeller Shaft.

Support the head of the pinion on a firm flat surface underneath the ram of a press. Place the propeller shaft assembly above it with the muff coupling splines aligned with the pinion splines. Set the shaft in line with the pinion and press down the propeller shaft until the lower end buts against the end of the pinion. This work must never be done when the pinion and bearings are assembled into the bevel casing.

Trueing up the Propeller Shaft Assembly.

The propeller shaft must run true with the pinion to within .003-in. of perfect accuracy. After pressing it on therefore set up the pinion and shaft between centres and set the shaft to attain the degree of accuracy required.

Refitting the Bevel Pinion Assembly to the Bevel Drive Casing.

If the original bevel and crown wheel are being refitted work can proceed as follows using the packing shims that were removed when dismantling, or new ones of the same total thickness. If a new pinion and crown wheel are to be fitted refer to the next section.

Having fitted the shims over the outer race against the flange, heat the neck of the bevel casing and slide the pinion assembly with propeller shaft fitted (see page 52) into the casing, pressing them home by hand. Hold the casing in a vice by either of the methods described in the dismantling procedure, push the oil seal housing down into place, and screw the lock-ring home tight.

The thickness of shimming required may vary if a new pinion is fitted. To determine the thickness use the Shimming fixture LET810.

Place the pinion assembly with bearings, etc., into the fixture from the 'cut-away' end; entering the roller bearing outer race - with no packing shims on it - into the bore of the fixture (Fig. 46).

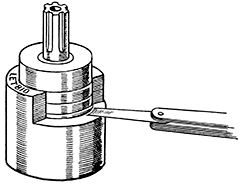

FIG. 46

The Bevel Pinion Shimming Fixture No. LET 810

Feeler gauge is in use checking clearance.

Rest the fixture with the ‘head' of the pinion on an accurate face plate, or against a straight-edge placed across them. Press the splined end of the pinion against the surface of the face plate or the straight-edge, so that it is in firm contact with it. This will give a small clearance between the under side of the outer race flange and the shimming fixture.

Check the extent of this clearance, using a feeler gauge through the cut¬away in the fixture between the flange and the ground face - see illustration. Make quite sure that the pinion head is in contact with the face plate other¬wise a false reading will be obtained.

Select packing shims equal in total thickness to the clearance as checked on the fixture. Remove the pinion assembly, etc., from the fixture, and fit the shims selected over the outer race against the flange. Refit the assembly to the fixture with these shims and check again on the face plate or straight-edge. The shims must just take up all the clearance that previously existed.

When correctly shimmed remove from the fixture and fit to the bevel casing as described in the previous section.

Refitting the Crown Wheel Shaft and Cover to Bevel Casing with new Crown Wheel.

This section refers only to the reassembly of the cover, etc., when new pinion and crown wheel are being fitted. If the original gears are being reinstated refer to page 60.

The bevel pinion assembly must have been fitted to the casing with the correct shims as determined by using the Shimming Fixture LET810 (Fig. 46).

With the bevel in place, and dowels fitted refit the cover and crown wheel shaft as described on page 60. Tighten the nuts down evenly and only a very little at a time. As tightening proceeds check the gears for freedom of meshing by turning the pinion frequently. At the very first indication that all the backlash is being taken up stop tightening. This shows that the gears are too tightly meshed and the cover must be removed. The Vice Tool LET788 can be used for turning.

Having removed it heat it up around the ballrace housing and draw the ballrace and shaft out. Remove one packing shim, refit the ballrace and shaft, and refit the cover. Tighten the nuts again evenly and slowly and check for freedom as before.

The aim is to get the cover bolted firmly to the casing leaving the least possible backlash between the gears that will give absolute freedom of running in all positions with a satisfactory degree of silence.

Usually the backlash is about .005-in.

If the cover can be pulled right up to the face with all nuts tight, and there is excess backlash, remove the cover, take out the ballrace, and add to the thickness of packing by putting in an additional shim or shims.

N.B. - The cover must be heated each time the ballrace is removed or refitted to it. Be extremely careful not to overheat it.

Refitting the Fixed Spindle.

Pass the fixed spindle through the crown wheel shaft, centralizing the spindle inner washer, to allow the threaded end to go into the cover. Tap the spindle home

Hold the other end in the Clamping Tool LET790 as when dismantling and turn it until the keyway registers with the one in the cover. Insert the 1/8-in. diameter round key pushing it down flush with the face.

Fit the outer washer and lock-ring and tighten the latter securely.

Refitting Bevel Drive Assembly to Swinging Fork.

If the swinging fork has been removed from the frame, push the propeller shaft through the torque tube, line up the studs on the casing with the holes in the flange on the fork and tap the casing forward until the faces meet. Fit the lock-washers and nuts and tighten.

Fit the assembly to the frame, see page 52.

The propeller shaft spring and universal joint are fitted next, and after refitting the bell the engine and gearbox assembly is reinstalled.

Should the engine and gearbox already be in place proceed as described in the next section.

Refitting the Bevel Drive to the Swinging Fork Assembly. (Power Unit in position.)

This entails lining up the socket of the universal joint with the propeller shaft to enable the shaft to be 'blind' fitted : the splines on the propeller shaft being brought into line with those in the joint socket to allow the former to enter. The swinging fork must be horizontal when refitting.

If the socket of the universal joint has got out of line it can be brought into position by lining it up with a piece of round steel bar or length of hard wood threaded up through the open end of the fork (the left hand torque tube). A bar not less than eighteen inches long and in. or slightly greater in diameter will be suitable.

Having lined up the universal joint, fit the spring over the front end splines of the propeller shaft. Insert the shaft into the torque tube and engage the splines with those in the universal joint. To do this the shaft will possibly have to be turned to get them to enter. It is usually more convenient to turn the crown wheel shaft. In case of difficulty the extreme front end of the propeller shaft splines can be very carefully tapered off to assist entry.

As the splines engage push the bevel casing forward up to the face of the torque tube. Fit the lock-washers and nuts and tighten fully.

Refit the rear brake cable and adjust the brake.