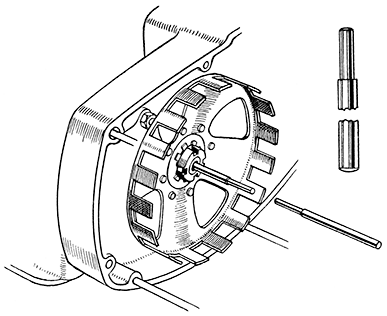

The clutch is operated from the lever at the rear of the gearbox through two thrust rods working inside the primary gear shaft (Fig. 18). These are packed with a special lubricant (L4 Absorbed Oil) during original assembly and this is sufficient in conjunction with oil holes drilled radially through the shaft to last indefinitely. They can be pushed out quite easily for lubrication if required after the gearbox is removed. When fitting note that one end of each is of reduced diameter. The reduced ends must meet in the shaft. To allow for the build-up of manufacturing tolerances one rod is listed in three alternative lengths, and the clutch lever pivot is eccentric; providing an adjustment for the lever.

Fig. 18 Arrangement of Thrust Rods when two are used

With the correct length of push rods and lever adjustment the horizontal distance between the centre of the clevis pin hole in the lever and the real end of the top of the gearbox should be 1/8-in. when the lever is held forward taking out all play between the thrust rods.